Key Takeaways:

- Insulated tools provide critical protection against electric shocks and arc flash hazards, safeguarding workers in high-voltage environments.

- Advanced features, including dual-layer insulation and compliance with international safety standards, combined with durable construction, ensure reliability and longevity.

- Ergonomic designs enhance handling, reduce fatigue, and facilitate precise work, particularly during prolonged tasks or when wearing gloves.

- Compliance with OSHA, IEC, and other regulatory standards is crucial for ensuring legal adherence, maintaining workplace safety, and minimizing liability.

- Growing industries, such as electric vehicles and renewable energy, are driving demand for high-performance insulated tools. Investing in quality tools is both a safety and operational priority.

Introduction to Insulated Tools

Professionals working with electrical systems face unique hazards every day. The use of specialized equipment, such as insulated tools, is critical not just for efficiency but for personal safety. Insulated tools offer reliable protection against electric shocks and reduce the risk of electrical accidents—making them an essential part of any electrician’s or technician’s toolkit. These tools are designed to withstand high voltages, providing robust protection against live electrical currents. To see diverse insulated tool options for multiple industries, visit Divergent Alliance. What distinguishes high‑performance insulated tools from conventional tools is their rigorous engineering, high level of craftsmanship, and strict adherence to international safety standards. Their development addresses the rapidly evolving challenges of industries, such as electrical, automotive, and renewable energy. As the complexity of electrical systems grows, so does the need for specialized tools designed with both safety and functionality in mind.

Key Features of High-Performance Insulated Tools

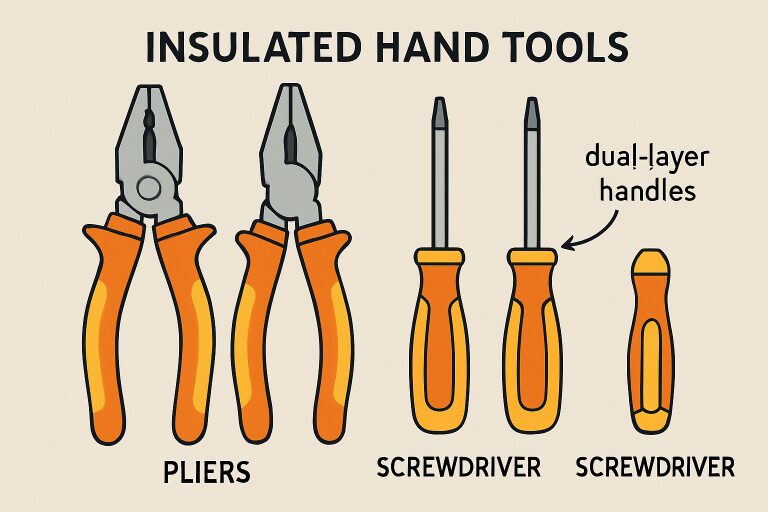

- Dual-Layer Insulation: The most advanced insulated tools feature a dual-layer insulation system, with an outer orange layer and a visible yellow inner layer. This safety feature quickly alerts professionals if the tool’s insulation is compromised, ensuring that only safe tools are in use at any given time.

- Compliance with International Standards: Leading manufacturers ensure that their tools adhere to globally accepted safety standards, including IEC 60900:2018. Compliance guarantees that the product has undergone voltage resistance and flame retardancy tests, making it suitable for use even in hazardous environments.

- Durability and Resistance: These tools are constructed with premium plastics and high-grade steel components, offering resistance to solvent exposure, cracking, and extreme temperatures. This attention to durability extends their service life and ensures consistent, reliable operation under all types of conditions.

Applications in the Electric Vehicle Industry

The dramatic rise of electric vehicles (EVs) has driven significant demand for high-quality insulated tools. EVs often operate at voltages far exceeding those found in typical household circuits, making safety-focused design an absolute necessity. Technicians working on battery modules, wiring harnesses, or system diagnostics must use insulated tools to comply with industry safety regulations and safeguard themselves from electric shock.

According to recent industry research, the global market for insulated tools is expected to continue expanding at an impressive rate, with a projected compound annual growth rate (CAGR) of 8.3% between 2022 and 2028. This growth is powered by surging EV adoption and a broader move toward electrification in transportation and manufacturing. Innovations in tool design and material science will likely make insulated tools even more effective and accessible in the years ahead.

Advancements in Insulated Tool Manufacturing

Modern insulated tool manufacturing is characterized by continuous innovation. Some top-tier manufacturers now use an injection molding process that encapsulates the tool in a tough, specialized nylon thermoplastic. This method fuses insulation directly to the tool, eliminating gaps or weak points, and significantly enhances resistance to mechanical stress, temperature fluctuations, and chemicals commonly found in industrial settings.

These advancements ensure that insulating layers maintain their integrity throughout the tool’s lifespan, reducing downtime and enhancing safety. Manufacturers also refine their designs with feedback from industry professionals, enabling them to address emerging risks and streamline maintenance and repair operations in rapidly evolving sectors such as renewable energy and automotive technology.

Importance of Ergonomic Design

User comfort and efficiency are also at the forefront of high-performance insulated tool design. Ergonomic handles contour precisely to the shape of a worker’s hand, minimizing fatigue and reducing the risk of repetitive strain injuries—even during extended use. Features such as anti-slip finishes, textured grips, and larger handle diameters provide added control, which is crucial for delicate or precise tasks. Ergonomics is especially beneficial when technicians wear gloves, enabling better handling without compromising dexterity.

Integrated design features ultimately boost productivity and help maintain safety standards. An article from Safety+Health Magazine explores why ergonomics plays a key role in reducing workplace hazards and occupational injury rates.

Compliance with Safety Regulations

Using insulated tools is more than a recommended safety measure; it is mandated by law in many work environments. For instance, standards such as OSHA 1910.335 require the use of insulated tools around exposed energized conductors. Regulatory compliance helps organizations avoid penalties and reduce insurance costs, while also ensuring a culture of safety. Adhering to standards is essential for workplace safety programs and ongoing training, ultimately protecting both individual technicians and company assets.

Final Thoughts

High‑performance insulated tools are indispensable for professionals working in electrical and related industries. Distinguished by innovative safety features, strict adherence to global regulations, excellent durability, and user-focused ergonomic design, these tools help create safer and more efficient work environments. As electrical systems become more advanced and prevalent across key industries, investing in the best insulated tools available remains the gold standard for worker safety and operational excellence.